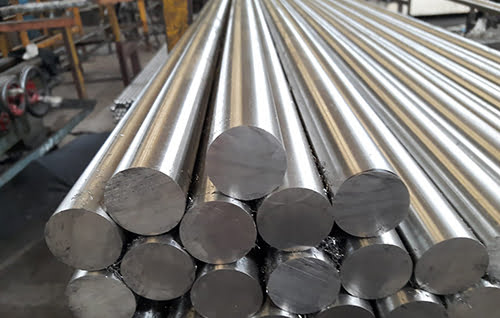

4140 Steel Bar Suppliers: Your Gateway to Quality Steel.In the world of metallurgy and manufacturing, finding a reliable supplier for specialized materials like 4140 steel bars is crucial. 4140 steel is a versatile and widely-used alloy known for its exceptional strength, durability, and suitability for a range of applications. This article will guide you through the process of choosing the right 4140 steel bar supplier while exploring the key attributes and applications of this remarkable material.

Understanding 4140 Steel

What is 4140 Steel?

4140 Steel Bar Suppliers: Your Gateway to Quality Steel.4140 steel is a low alloy steel that contains chromium and molybdenum, making it exceptionally strong and heat-resistant. It is often referred to as “chromoly” steel and is used in a variety of industries, including aerospace, automotive, and oil and gas.

Properties of 4140 Steel

4140 steel boasts a set of remarkable properties that make it a sought-after material:

- High tensile strength

- Excellent impact resistance

- Good fatigue strength

- High toughness

- Heat treatable

Applications of 4140 Steel

4140 steel is a versatile alloy known for its exceptional properties, making it a preferred choice for a wide range of applications across various industries. Its remarkable combination of strength, durability, and heat resistance allows it to excel in numerous roles. In this section, we will explore in detail some of the key applications of 4140 steel.4140 Steel Bar Suppliers: Your Gateway to Quality Steel.

Aerospace Industry

The aerospace industry demands materials of the highest quality to ensure the safety and reliability of aircraft. 4140 steel is a prime choice for numerous aerospace components, particularly in the landing gear systems. The high tensile strength and excellent impact resistance of 4140 steel are crucial in this context.

Aircraft landing gear must withstand tremendous stress during takeoffs and landings. 4140 steel’s toughness and heat-treatable properties ensure that it can endure the rigors of flight operations. Moreover, its ability to maintain its structural integrity even in extreme conditions, such as sudden impacts and temperature fluctuations, is of paramount importance for aviation safety.4140 Steel Bar Suppliers: Your Gateway to Quality Steel.

Automotive Sector

4140 Steel Bar Suppliers: Your Gateway to Quality Steel.In the automotive industry, 4140 steel plays a vital role in the manufacturing of various components. The demand for lightweight yet sturdy materials in the automotive sector is met by this alloy. Applications include crankshafts, axles, and drive shafts.

4140 Steel Bar Suppliers: Your Gateway to Quality Steel.Crankshafts are critical engine components that convert the reciprocating motion of the pistons into rotational motion. The high strength and fatigue resistance of 4140 steel make it ideal for this application, ensuring the engine’s reliability and performance. Additionally, 4140 steel’s heat-treatable nature allows for precise engineering, improving fuel efficiency and reducing emissions.

4140 Steel Bar Suppliers: Your Gateway to Quality Steel.Axles and drive shafts also benefit from the alloy’s robust properties. These components must bear heavy loads and endure constant stress, particularly in larger vehicles and trucks. 4140 steel ensures that these parts can maintain their structural integrity, contributing to vehicle safety and longevity.

Oil and Gas Drilling Equipment

The oil and gas industry operates in some of the harshest and most challenging environments on Earth. Equipment used in drilling operations must be able to withstand extreme pressures and temperatures, and 4140 steel is an ideal choice for such applications.

Drill collars and drill pipe tool joints are often made from 4140 steel due to its exceptional strength and heat resistance. These components are integral to the drilling process, as they connect the drilling rig to the drill bit. The ability of 4140 steel to endure the punishing conditions of deep drilling ensures the efficiency and safety of oil and gas exploration.

Moreover, the alloy’s high tensile strength and good fatigue resistance are invaluable in preventing equipment failure during drilling operations. This is not only essential for the safety of personnel but also for preventing costly downtime and damage to drilling equipment.

Machinery and Tool Manufacturing

In the world of machinery and tool manufacturing, 4140 steel finds applications in various structural and critical components. This includes gears, shafts, and mold dies, to name a few.

Gears are vital components in machinery, transmitting power and motion between different parts. 4140 steel’s high strength and toughness ensure that gears can endure the stresses and pressures placed upon them, resulting in smooth and efficient operation.4140 Steel Bar Suppliers: Your Gateway to Quality Steel.

Shafts are used in numerous applications across industries, from industrial machinery to automotive systems. The durability of 4140 steel is a major advantage, as it ensures the long-term reliability of shafts, reducing maintenance costs and downtime.

Mold dies used in manufacturing processes benefit from 4140 steel’s heat-treatable properties. These properties enable precise shaping and forming, contributing to the production of high-quality components in various industries.

4140 steel’s widespread applications across multiple industries attest to its versatility and exceptional properties. Whether it’s in aerospace, automotive, oil and gas, or machinery and tool manufacturing, this alloy consistently demonstrates its strength, durability, and heat resistance. Choosing 4140 steel for specific applications ensures that the end product will be reliable, safe, and cost-effective.4140 Steel Bar Suppliers: Your Gateway to Quality Steel.

Choosing the Right 4140 Steel Bar Supplier

When it comes to sourcing 4140 steel bars, selecting the right supplier is pivotal to ensuring the quality and reliability of your materials. Here are some key factors to consider:

Reliability and Reputation of Suppliers

4140 Steel Bar Suppliers: Your Gateway to Quality Steel.Look for suppliers with a track record of reliability and positive reviews from customers. Trustworthiness is a must in the steel industry.

Quality and Certification

4140 Steel Bar Suppliers: Your Gateway to Quality Steel.Ensure that the supplier provides steel bars that meet industry standards and come with appropriate certifications. Quality assurance is vital for your projects.

Pricing and Cost Considerations

4140 Steel Bar Suppliers: Your Gateway to Quality Steel.While competitive pricing is important, don’t compromise on quality for a lower price. Evaluate the supplier’s pricing structure and weigh it against the quality of the product.

Delivery and Shipping Options

Consider the supplier’s ability to deliver on time and their shipping options. Reliable delivery can save you time and money in the long run.

Customer Support and Communication

Good communication is essential. Opt for suppliers who are responsive and willing to assist with any inquiries or concerns.

Case Studies: Successful Implementations of 4140 Steel

To illustrate the effectiveness of 4140 steel, let’s explore a couple of real-world case studies where this material has made a significant impact.4140 Steel Bar Suppliers: Your Gateway to Quality Steel.

Case Study 1: Aerospace

In the aerospace industry, 4140 steel is widely used in landing gear components due to its strength and durability. It ensures safe and reliable landings for millions of passengers worldwide.

Case Study 2: Oil and Gas

In the oil and gas sector, 4140 steel is employed in drilling equipment, where it must withstand extreme pressures and temperatures. Its robust properties make it a preferred choice.

Maintenance and Care of 4140 Steel Bars

To ensure the longevity of 4140 steel bars in your applications, regular maintenance is crucial. Regular inspection and cleaning can extend the life of these bars, saving you both time and money in the long run.

Conclusion

Selecting the right 4140 steel bar supplier is essential for the success of your projects. The quality, reliability, and reputation of your supplier can impact the performance and durability of the materials you use. With the versatility and remarkable properties of 4140 steel, it has become a staple in various industries, proving its worth time and time again.

FAQs

- What makes 4140 steel bars stand out in the industry? 4140 steel bars are known for 4140 Steel Bar Suppliers: Your Gateway to Quality Steel.their high strength, excellent impact resistance, and heat-treatable properties, making them suitable for a wide range of applications.

- How can I ensure the quality of the 4140 steel bars I purchase? To ensure quality, choose a reputable supplier with the necessary certifications and a track record of reliability.

- What are the common applications of 4140 steel? 4140 steel is commonly used in aircraft landing gear, automotive components, oil and gas drilling equipment, and structural parts in machinery.

- Why is communication with the supplier important? Effective communication with the supplier ensures that your needs are met, and any concerns or inquiries are addressed promptly.

- What maintenance practices should I follow for 4140 steel bars? Regular inspection and cleaning are essential for maintaining the longevity and performance of 4140 steel bars in various applications.