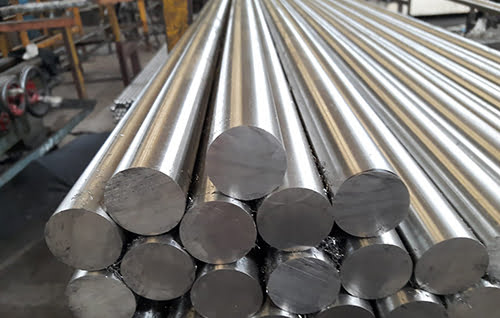

Introduction to Quenched Steel

Quenched steel, the secret ingredient that adds strength and durability to countless structures and machinery. You may have heard of it before, but do you really know what it is? Well, get ready to dive into the fascinating world of quenched steel as we unravel its mysteries and explore its incredible properties. Whether you’re a construction enthusiast or an engineering aficionado, this article will provide you with all the essential information about this remarkable material. So buckle up and prepare to be amazed by the power of quenched steel!

The Process of Quenching

The process of quenching is a crucial step in the manufacturing of quenched steel. It involves rapidly cooling the heated metal to achieve specific properties and characteristics. This rapid cooling is achieved by immersing the hot steel into a liquid medium, such as water, oil, or polymer solutions.

During quenching, the high temperature of the metal causes its crystal structure to change. As it cools down quickly, this new structure becomes locked in, resulting in increased hardness and strength. The speed at which the cooling occurs plays a significant role in determining these properties.

Quenching can be performed using different methods depending on factors like the type of steel and desired outcome. For instance, water quenching provides maximum hardness but may cause distortion or cracking due to rapid cooling rates. Oil quenching offers more controlled cooling and reduces the risk of cracking.

In addition to enhancing hardness and strength, quenching can also improve other desirable properties like wear resistance and toughness when done correctly.

Understanding and properly executing the process of quenching are essential for achieving optimal results with regards to metallurgical properties in quenched steels.

Types of Quenched Steels

When it comes to quenched steel, there are several types available that cater to different applications and requirements. One common type is water-quenched steel, which involves rapidly cooling the heated metal by immersing it in water. This process creates a hardened surface that enhances the strength and durability of the steel.

Another type is oil-quenched steel, where the heated metal is submerged in oil instead of water. Oil quenching provides a slower cooling rate compared to water, resulting in less distortion and cracking. This makes it suitable for parts that require a balance between hardness and toughness.

For specific applications that demand even higher hardness, salt bath quenching may be used. In this method, the metal is immersed into molten salts at elevated temperatures. The unique properties of these salts allow for precise control over the quenching process, resulting in exceptionally hard steels.

Additionally, air-quenchable steels are gaining popularity due to their ability to be cooled in ambient air without additional mediums such as oils or waters. These steels offer improved machinability while still providing desirable mechanical properties after heat treatment.

Each type of quenched steel has its own advantages and considerations depending on factors like desired hardness level, part geometry, and application requirements. It’s important to carefully select the appropriate type based on your project needs to ensure optimal performance.

Remember – when working with any form of quenched steel – proper safety precautions should always be taken due to potential hazards associated with high temperatures and rapid cooling rates involved in the process!

Benefits of Using Quenched Steel

Quenched steel offers a wide array of benefits that make it an attractive choice for various applications. One key advantage is its superior strength and hardness. Through the quenching process, steel undergoes rapid cooling, resulting in a hardened structure that can withstand heavy loads and extreme conditions.

Another benefit of using quenched steel is its excellent wear resistance. The hardened surface created during quenching provides protection against abrasion, extending the lifespan of components made from this material. This makes it ideal for use in industries such as automotive manufacturing and mining, where parts are subjected to constant friction and wear.

Additionally, quenched steel exhibits improved toughness compared to other types of steel. It has the ability to absorb energy without fracturing or breaking under intense pressure or impact. This makes it suitable for applications requiring high-strength materials, such as construction equipment or structural components.

Furthermore, quenched steel offers enhanced dimensional stability and precision machining capabilities. Its uniform microstructure ensures consistent performance throughout the material’s lifespan and allows for tight tolerances in manufacturing processes.

Moreover, quenched steels have good corrosion resistance properties when combined with appropriate alloying elements or protective coatings. This extends their durability even when exposed to harsh environments or corrosive substances.

The benefits of using quenched steel make it a preferred choice in many industries where strength, durability, wear resistance, toughness,and dimensional stability are crucial factors for success.

Common Applications of Quenched Steel

Quenched steel, with its exceptional strength and durability, finds a wide range of applications in various industries. One common application is in the automotive industry, where quenched steel is used to manufacture critical components like gears, shafts, and axles. These parts are subjected to intense forces and wear during operation, making the superior hardness and toughness of quenched steel essential for their performance.

In the construction sector, quenched steel is often used to create high-strength structural elements such as beams and columns. The ability of quenched steel to withstand heavy loads makes it ideal for supporting large structures like bridges or skyscrapers. Additionally, its resistance to corrosion ensures longevity even in harsh environments.

The oil and gas industry also heavily relies on quenched steel for drilling equipment due to its excellent mechanical properties. Tools such as drill bits made from quench-hardened steel can endure extreme temperatures and pressures encountered during well drilling operations.

Furthermore, manufacturers of cutting tools benefit from using quenched steel alloys because they provide enhanced hardness and sharpness necessary for precision machining processes. This includes applications such as milling cutters, saw blades, drills, or dies.

Challenges and Considerations when Working with Quenched Steel

While quenched steel offers numerous benefits, it is essential to be aware of the challenges and considerations that come with working with this material. One significant challenge is the rapid cooling rate during the quenching process. This can lead to internal stresses within the steel, which may result in distortion or cracking.

Another consideration is the potential for brittleness in quenched steel. The high hardness achieved through quenching can make it more susceptible to fractures under certain conditions. Therefore, careful handling and proper heat treatment are crucial to ensure optimal performance.

Additionally, working with quenched steel presents machining difficulties due to its hardness. Special tools and techniques may be required for cutting, drilling, or shaping this material effectively.

Corrosion resistance is another aspect worth mentioning when considering working with quenched steel. While some types of quenched steels exhibit excellent corrosion resistance properties, others may require additional protective measures such as coatings or platings.

Cost should also be taken into account. Quenching involves an extra step in the manufacturing process and requires specific equipment and expertise. Thus, it’s important to evaluate if using quenched steel aligns with your project budget.

Conclusion: Is Quenched Steel Right for Your Project?

After exploring the process, types, benefits, and applications of quenched steel, you may be wondering if it is the right choice for your project. Well, the answer depends on several factors.

First and foremost, consider the specific needs and requirements of your project. Quenched steel offers exceptional strength and hardness properties, making it ideal for applications that require high durability. If your project involves heavy machinery components or tools that undergo intense wear and tear, quenched steel could be a suitable option.

Furthermore, if you are looking to improve the mechanical properties of a material by enhancing its hardness or stability while maintaining good toughness characteristics, quenching might be worth considering. However, keep in mind that this process can also introduce some challenges.

One challenge when working with quenched steel is its increased brittleness compared to other materials. This means that careful handling and appropriate design considerations are necessary to prevent issues such as cracking or fractures under stress.

Additionally, it’s important to note that not all steels can be effectively hardened through quenching. Some alloys may not respond well to this heat treatment method or may require additional steps such as tempering after quenching to achieve optimal results.

Whether or not quenched steel is right for your project will depend on factors such as desired mechanical properties, specific application requirements, budget constraints, and available alternatives. It is always recommended to consult with metallurgical experts or experienced engineers who can provide valuable insights based on their knowledge and expertise.

In conclusion, understanding the process behind quenched steel along with its various types and benefits gives us a glimpse into its potential advantages in certain applications. However,e careful consideration should always be given before incorporating this heat treatment technique into any project.